International Society of Beverage Technologists

ISBT is the only organization whose sole interest is the technical and scientific aspects of soft drinks and beverages. With members from around the world, membership is open to any person engaged in the science, technology, or production of soft drinks or beverages, including those suppliers to the beverage industry whose principal occupation is substantially technical in nature. This includes individuals employed by bottlers, franchise companies, packaging, flavor, ingredient, and equipment suppliers who are engaged in scientific or technical positions.

ISBT enhances the promotion, development, and dissemination of knowledge relating to the art and science of beverage technology for the non-alcoholic beverage industry. Focus areas of activity include (but are not limited to) beverage formulation, production, packaging, equipment, and distribution. We do this by:

- Providing forums for scholarly discussion

- Stimulating the application of science in the industry

- Publishing voluntary technical guidelines and best practices

- Encouraging and fostering research

Most of our activities center around our annual conference (BevTech), our regional events (Asia Pacific, Canada, Europe, India, and Latin America), and our 9 technical committees:

- Beverage Gases

- Beverage and Ingredient R&D

- Beverage Operations & Processing

- Packaging Technology

- Quality

- Retail Equipment and Fountain Technology

- Sanitation and Microbiological Control

- Sweetener

- Water Quality & Treatment

ISBT also has a series of online microlessons designed to provide an important and easily available resource for our global community of beverage professionals. The Beverage Institute by ISBT® currently offers 9 courses covering everything from the Fundamentals of Beverage Technology to more specialized courses on Microbiology, Sweeteners, Gases, Water, and more. More information about these courses can be found at https://www.isbt.com/isbt-beverage-institute.asp.

Membership rates, benefits, and more can be found at https://www.isbt.com/membership.asp. KBI members can enter Kombucha in the Discount Code field to get $50 off your first year’s membership.

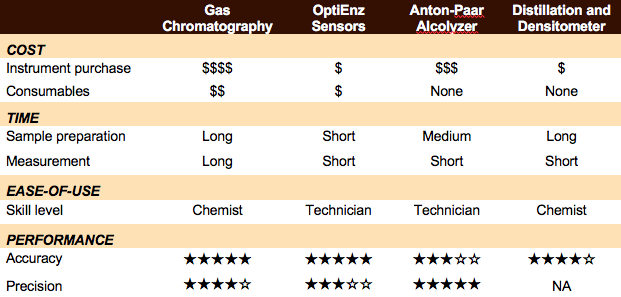

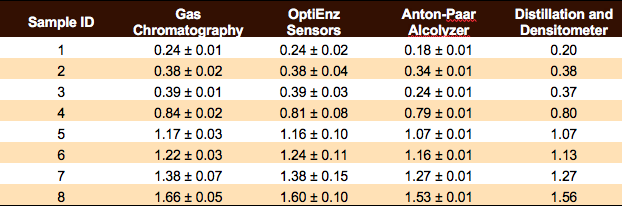

Headspace gas chromatography – flame ionization detection (HS/GC-FID) measurements and sample preparation were performed using AOAC methods for determination of ethanol in kombucha (AOAC 2016.12). Analysis was completed on a HP 5890 Series II gas chromatograph (four measurements per sample) with a Restek Stabilwax-DA capillary column using nitrogen as the carrier gas, and resolution of methanol, ethanol, isopropanol, 1-propanol, and acetone was possible using this setup. A calibration curve was constructed using Cerilliant ethanol standards purchased from Sigma-Aldrich.

Headspace gas chromatography – flame ionization detection (HS/GC-FID) measurements and sample preparation were performed using AOAC methods for determination of ethanol in kombucha (AOAC 2016.12). Analysis was completed on a HP 5890 Series II gas chromatograph (four measurements per sample) with a Restek Stabilwax-DA capillary column using nitrogen as the carrier gas, and resolution of methanol, ethanol, isopropanol, 1-propanol, and acetone was possible using this setup. A calibration curve was constructed using Cerilliant ethanol standards purchased from Sigma-Aldrich. Ethanol measurements were performed using an OptiEnz Sensors ethanol sensing system. The instrument was calibrated over 10 minutes using prepared ethanol standards. Ethanol measurements (six measurements per sample) were made by diluting 0.1 mL of sample into 50 mL of buffer, immersing the sensor probe into the dilute solution and allowing the system to stabilize for three minutes.

Ethanol measurements were performed using an OptiEnz Sensors ethanol sensing system. The instrument was calibrated over 10 minutes using prepared ethanol standards. Ethanol measurements (six measurements per sample) were made by diluting 0.1 mL of sample into 50 mL of buffer, immersing the sensor probe into the dilute solution and allowing the system to stabilize for three minutes. Density and Alcolyzer measurements were performed using an Anton-Paar DMA 4500 M-EC with Enhanced Calibration for Ethanol paired with an Alcolyzer Beer ME module and Sample Handling Unit (Xsample 22). The instrument was calibrated with degassed, deionized water and achieved a density measurement of 0.99820 ± 0.00001 g/mL at 20ºC. Sample analysis (six measurements per sample) was performed by pumping 40 mL of sample through the system, bringing the sample temperature to 20.00 ± 0.01°C, and then collecting density and Alcolyzer measurements.

Density and Alcolyzer measurements were performed using an Anton-Paar DMA 4500 M-EC with Enhanced Calibration for Ethanol paired with an Alcolyzer Beer ME module and Sample Handling Unit (Xsample 22). The instrument was calibrated with degassed, deionized water and achieved a density measurement of 0.99820 ± 0.00001 g/mL at 20ºC. Sample analysis (six measurements per sample) was performed by pumping 40 mL of sample through the system, bringing the sample temperature to 20.00 ± 0.01°C, and then collecting density and Alcolyzer measurements. Kombucha samples (100 mL per sample) were distilled according to the TTB-recommended distillation-specific gravity method (AOAC 935.21). Density measurements (one measurement per sample) were made using the Anton-Paar densitometer.

Kombucha samples (100 mL per sample) were distilled according to the TTB-recommended distillation-specific gravity method (AOAC 935.21). Density measurements (one measurement per sample) were made using the Anton-Paar densitometer.